Prefabrication in Hybrid Construction: Advantages and Examples

The construction industry is gradually in the process of transforming and becoming more efficient, sustainable and innovative through prefabrication.

Especially in the context of the structural type separating the Thailand building into Hybrid construction – conventional as well as modern material such as steel, concrete, bamboo, and timber; prefabrication has established a significant position.

Besides helping to optimize construction procedures, this approach also improves the structural function and visual properties of the constructions.

In this blog post we shall discuss about Prefabrication in Hybrid Construction, the benefits and these existing structures giving a glimpse of the future.

An exploration to reveal about, Prefabrication in Hybrid Construction

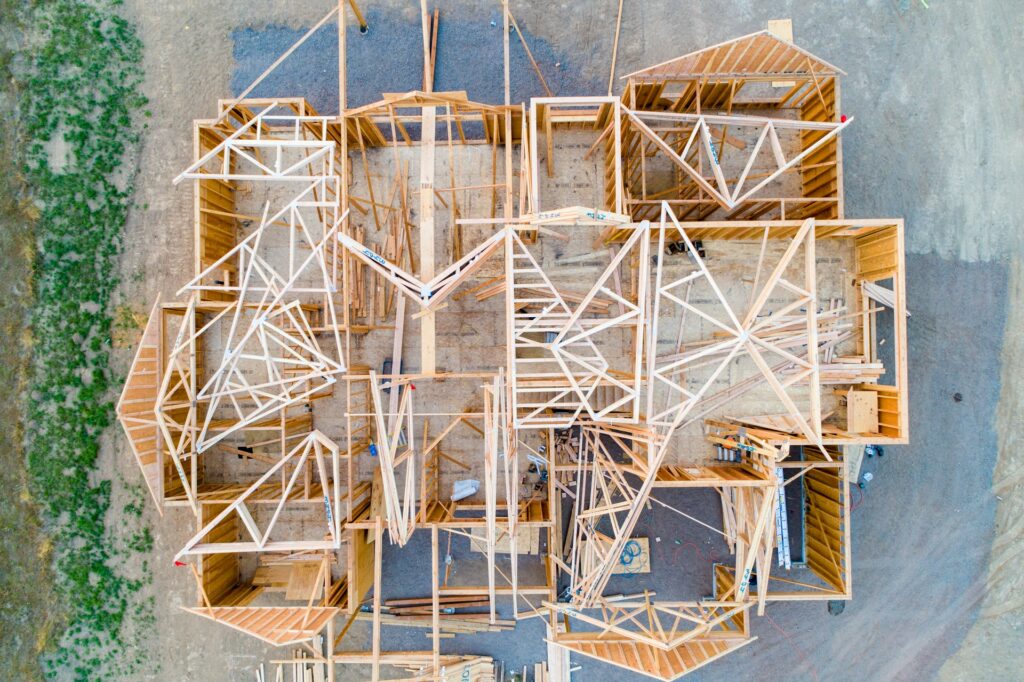

Prefabrication simply means creation of building components away from the construction site always in factories before they are transported and installed at site.

The use of prefabrication in hybrid construction means that a number of different materials must be combined into efficient and effective structures.

Blending occurs when different materials possessing different attributes are used in the construction process to fulfill some purposes.

For instance:

Steel and Timber:

Steel offers stiffness and sturdiness which timber brings natural feel to the building and also the aspect of being environmentally friendly.

Lightweight and visually adequate structures are realized through steel beams and wooden panels that can be joined with equal ease.

Concrete and Bamboo:

Pre-cast concrete products are combined with bamboo structures to ensure the structures are strong and at the same time, can be reused through recycling.

This combination is being widely used in the framework of sustainable architecture.

Glass and Metal:

Modern façade construction focuses on extensive application of glass and aluminum thin coats or Fachwerks in the form of hybrid panels.

The proposed hybrid approach leverages these two materials and their respective trips to keep up with the prefabrication approach as an efficient method for assembling these intricate systems.

Advantages of Prefabrication in Hybrid Construction

The incorporation of prefabrication in hybrid construction bids several compelling benefits:

Enhanced Efficiency

Speed of Construction: Prefabrication allows concurrent construction in that the constructional components can be collected in factories while elsewhere on the site groundwork is being made. This goes an extended way to shorten the project duration.

Precision and Quality Control: Factory conditions provide full control over the processes executed at plants, which decreases the probability of errors on site.

Sustainability

Reduced Material Wastage: With the use of off-site construction, components of the total building can be fabricated, and at the same time reducing wastage of materials.

Energy Savings: It saves energy during construction since few machines and man power are required on site during erection.

Recyclable Materials: Other features of hybrid systems include use of renewable such as the use of bamboo and recyclable such as steel making hybrids systems even more sustainable.

Cost-Effectiveness

Lower Labor Costs: This production methodology also translates to minimum on site personnel needed for production besides the fact that factory-based manufacturing implies less costs.

Minimized Delays: Ideally, any form of climate or site related issues have minimal effect on the construction of prefabricated buildings which, in turn makes it possible to achieve better budgets and time projections.

Design Flexibility

Customized Solutions: In this case prefabrication facilitate combination of hybrid material which also challenge the architectural creativity in terms of design.

Modular Systems: Hybrid components for prefabrication may be developed for construction and deconstruction work, leading to flexible structures in the future for alteration.

These benefits show why prefabrication is suitable for steel hybrid constructions across residential and commercial structural work to infrastructure projects.

Notable Examples of Prefabrication in Hybrid Construction

Several groundbreaking projects showcase the potential of prefabrication in hybrid construction:

1. The Bullitt Center America, Seattle

As one of the greenest commercial buildings worldwide, the Bullitt Center use steel, timber and concrete in its construction through prefabrication.

Pre-fabricated timber beams and steel connector ages were used thereby making the structure highly sustainable and energy efficient.

The results are an excellent fine architectural appearance, practicality, and an illustration of how prefabricated hybrid façade and envelope systems are possible to be aesthetically and structurally pleasing.

2. Mjøstårnet, Norway

This world’s tallest timber building consists of pre-fabricated timber framing system with steel reinforcement to produce an 18-story structure.

Prefabricated hybrid joinery allowed generous construction assembly while ensuring the longevity of the construction.

The new towering hybrid structure of the Mjøstårnet building fully demonstrates the opportunities that prefabrication provides.

3. EcoCocon Straw Panels, Europe

EcoCocon is the further development of the prefabricated straw panels which are connected to timber framework.

These panels are integrated with hybrid construction of homes to generate energy efficient and carbon negative residences.

The accurate combination of materials that can be afforded thru prefabrication provides good thermal and structural insulation.

4. The Green Village Bali – Indonesia

This is a regarded sustainable residential development built around the principles of green housing that employs pre-fabricated bamboo and concrete to construct bearable homes.

Stations and other structural features of bamboo are pre-coated and fabricated elsewhere, and then bolted with concrete pedestals onsite.

The outcome is a fusion of natural look together with structural features that guarantee long lasting structures.

The instances discussed in this article illustrate how prefabrication is reshaping hybrid building, and how architects and engineers can thus innovate with new prefabricated solutions.

Conclusion

Prefabrication in hybrid construction can be considered as an effective instrument for solving the problems concerning modern construction.

This research area has a potential to allow for constructing structures that are effective, green, and aesthetically appealing, by joining materials with synergistic characteristics.

Introduction of Pre fabrication processes is an effective method to have better control on the buildings, faster execution and less harm to the environment – factors which are viable in the modern world.

These are just a fraction of the possibilities of what hybrid designs can offer to the future of construction, and as the technology of prefabrication improves we will be able to find more creative uses of these new methods.

Starting from the environmentally friendly construction of homes right up to mega structures, it holds the key to transformations which in the future are aimed at making innovation the platform for sustainable construction.

Also read: Prefabrication: A Cost-Effective Solution for Affordable Housing